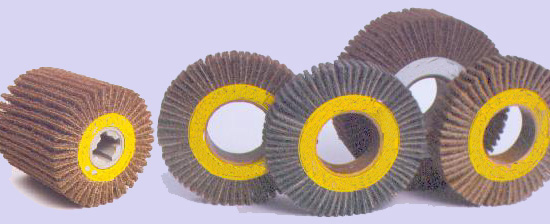

Flap Brushes - Plain

Our Flap/Disk/Spiral wound Brushes and Wheels combines the characterestics of Aluminium Oxide and Silicon Carbide. These products are applicable for use on both ferrous and non-ferrous metals.

They are available in :

- Non-woven Abrasives

- Coated Abrasives

- Interleaved ( Combination of both )

- Non-woven

- Felt.

Dia: 100 to 600 and

Length: 100 to 200 mm.

Spirally wound - Wheels

Spiraly wound wheels are unmatched in production and maintenance operations. Use them on portable power tools, bench motors, floor lathes and automatic or semi-automatic equipment to clean, deburr, blend, finish or polish all types of metals, composites or plastics.

An Extensive Range of Applications

These wheels can be used on many types of metal to create a

uniform, burr-free surface.

| Deburring | Stamped parts (ferrous, non-ferrous, special metals); aircraft components; surgical instruments; aluminum extrusions; machined metal components. |

| Edge Radiusing | Contours; grindlines; brazed extrusions; machined parts; jet blades. |

| Blending & Finishing | Contours; grindlines; brazed surfaces; airfoils of jet blades; compressor shafts; control panels; nameplates. |

| Polishing | Gun barrels, valve spools; machined shafts; golf club heads; other machined parts prior to plating or other subsequent operations. |

Flap Brushes (Surface Cond. Material)

These unique Flap Brushes are specially prepared using surface conditioning Materials and are a combination of aluminum oxide coated abrasive and abrasive material. They are designed for a variety of surface finishing and blending operations on a large variety of workpieces.

Deburring Wheel

Available with either silicon carbide or aluminum oxide minerals, our Deburring wheels help manufacturers of high-tolerance parts meet increasingly stringent product quality and production efficiency requirements.

Aggressive and smooth running

They are excellent for deburring and polishing titanium, special alloys,

composites and plastics. They are specially designed to minimize heat

buildup on the work surface. They run smoothly providing greater

operator comfort, safety and control …especially beneficial when

working with valuable parts.

Cool operation protects delicate parts

The open web construction of these wheels allows air to circulate

across the work surface. This helps prevent overheating that causes

discolouration and warping of thin and delicate materials.

Long life saves money

Extensive customer tests show that our deburring wheels last much

longer than other non-woven products while maintaining consistent

performance and uniform wheel wear. More production parts per

wheel means money saved.

Clean and safe

Nuisance dust from expended abrasive is greatly reduced compared

to other types of non-woven wheels. And, there are no flying wires to

endanger operators as with wire wheels.

Flap Brushes - Impregnated

Flap brushes (impregnated) deliver a consistent finish and a uniform rate of cut. As they are used the flaps wear away to continually expose new abrasive. There is a full line that complements the Flap bushes line to give you the best possible finish in the least time.

They are made using Premium Aluminum Oxide mineral and Silicon Carbide. Incorporates a grinding aid (excellent for stainless).

Flap Brushes - Plain

Our Flap Brushes (plain) deliver a consistent finish and a uniform rate of cut. They are non-loading, non-glazing and non-dulling.

As they are used the flaps wear away to continually expose new abrasive. These brushes can be shaped to fit any desired contour, even a compound radius.